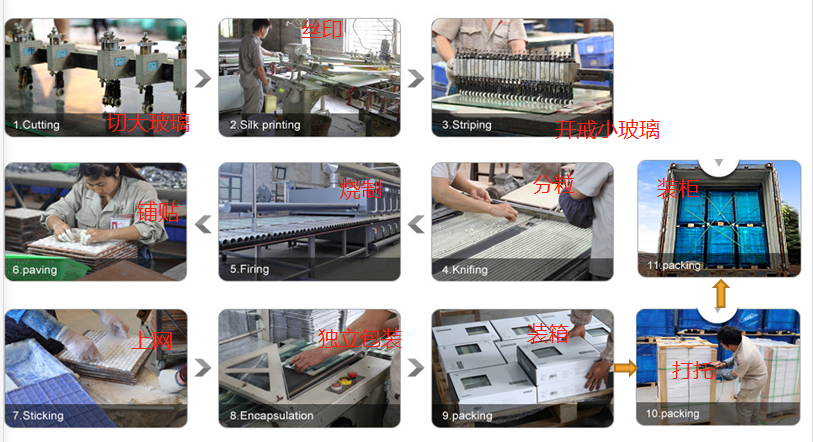

Glass mosaic manufacturing process

Glass is mainly divided into two categories: flat glass and deep-processed glass, of which there are three main types of flat glass: lead-up flat glass (slotted and non-slotted), flat-drawn flat glass and float glass. Deep-processed glass is made of flat glass and has a wide range of applications. If you want to know how to make and install glass mosaics, let me take a look.

1. Cutting & Toning

cut each piece of 2.44m*1.83m into 600mm*600mm, color

2. Silk Printing

- make the background color required by the customer, the screen printing process is 8 minutes

- Seal oil – add a layer of white paint on top of the background color, the process is 5 minutes

- drying – Glass mosaic manufacturing process

3. Striping

cut into 15*15, 20*20, 23*23, etc. according to customer size

Machine cutting-manual cutting into strips-machine breaking into 15*15, 20*20, 23*23, etc. sizes

4. Firing

Burn the corresponding surface according to the customer’s requirements, such as uneven surface (when making the uneven surface, you need to place the corresponding carved plate on the glass)

Put it in a 760 degree furnace and burn for 50 minutes. The finished product is about 80 degrees. If you need to make ice cracked noodles, place it in cold water immediately after the product is burned. (Note: the greater the temperature difference, the better the ice cracking effect)

5. Paving

allocate the quantity according to the proportion required by the customer

6. Sticking

First apply glue on the net (usually hexagonal PVC net, the glue ratio is 25g/square) Glass mosaic manufacturing process

View Our Glass Mosaic

-

Glass Mosaic

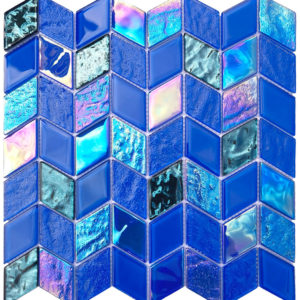

Iridescent Symphony Tile Glass Mosaic

-

Glass Mosaic

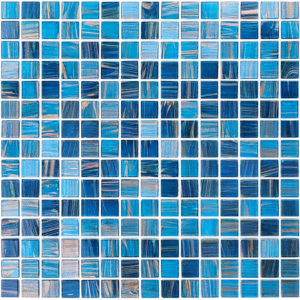

Blue Copper Blend Pool Mosaic

-

Glass Mosaic

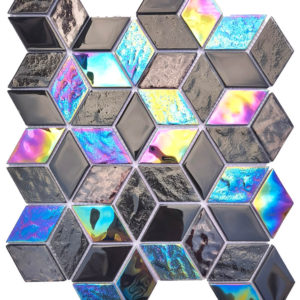

Rainbow Blue Glass Mosaic Tile

-

Glass Mosaic

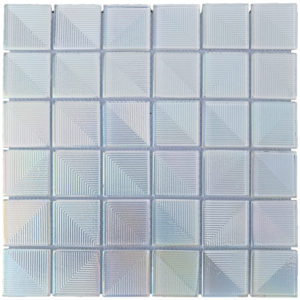

Iridescent Glass Mosaic Backsplash

-

Glass Mosaic

Electroplating Glass Mosaic Tile

-

Glass Mosaic

Iridescent Glass Mosaic Tile for Pool

-

Glass Mosaic

Square Metallic Glass Tile for Wall

-

Glass Mosaic

Glass Paste Mosaic Tile for Showroom