■ Introduction to Stone Mosaic Tile

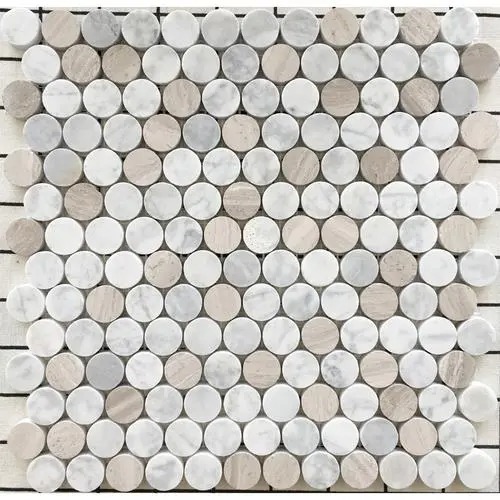

Stone mosaic tile is a mosaic made by cutting, cutting and polishing natural stone into mosaic blocks of various specifications and shapes.

■ Characteristics of stone mosaic tile

Decorating walls or floors with this material not only retains the rustic feel of the natural stone itself, but also enriches the patterns, with the characteristics of natural, elegant, durable and never fading.

■ Common specifications

20×20mm, 25×25mm, 30×30mm, the thickness is generally between 20mm~40mm.

■ Scope of application

Hotel, KTV, TV background wall, sofa background wall, etc.

■ Stone mosaic tile installation process

Installation preparation:

Stone renovation:

a. After completing the flat hard bottom base surface, according to the overall layout design, correctly outline or pull up the auxiliary line on the base surface to be installed to determine the specific installation position.

b. Prepare appropriate base material for pasting (it is recommended to use tile adhesive or white cement + glue and putty powder) and caulking agent (recommended to use environmentally friendly moisture-proof caulking agent).

c. Uncover the backing paper between each mosaic sheet, but keep the grid cloth.

Description of specific installation steps:

Apply adhesive:

Remove oil, dust and loose objects on the working base surface; repair base surface defects; wet the working base surface until there is no clear water; use a pre-selected and adjusted adhesive to apply a thin layer on the base surface evenly Bottom, and then evenly smear a thicker layer of adhesive on the bottom layer.

Mounting products:

After spreading the adhesive evenly with a toothed scraper, the prepared mosaic products can be installed.

Flat surface:

In order to ensure the horizontal flatness of the installation surface and ensure that each stone is evenly and firmly bonded, the surface of the product can be slapped with an elastic horizontal wood wrapped with flannel or sponge. Clean the surface: In order to keep the mosaic surface clean and not stick to the adhesive or white cement when paving, it is recommended to arrange an assistant to clean the surface with a soaked and dried sponge to prevent the adhesive or white cement from solidifying on the stone. Particle surface.

Joint preparation:

After laying the product for at least 24 hours, start the caulking work. If the caulking base is too dry, it can be properly moistened.

Jointing:

After preparing the caulking agent in an appropriate proportion, use a special caulking tool for caulking.

a. Press the caulking material completely into the gap, and the depth of the caulking is confirmed by the designer;

b. The caulking construction should be cleaned for the first time within 10 minutes after the completion of the construction, and the caulking agent on the surface of the product should be removed with a sponge that has been soaked and dried;

c. After the sealant is cured (depending on the weather, about 12 hours), clean the stains on the surface of the product with clean water again.

Maintenance:

a. After the mosaic is installed, use a vacuum cleaner to clean the dust, fill it with liquid marble glue, refurbish it after curing, and clean the crystal after polishing.

b. Anti-slip: The anti-slip properties of the stone after the mosaic crystal surface process should reach the anti-slip standard.

c. Appearance: The color of the stone passing through the crystal face cannot be changed. The surface must not have traces of crystal hardening agent, steel wool traces and scratches, and the whole is dry, clean, and uniform in brightness.

■ Precautions for stone mosaic construction

The floating dust on the wall is cleaned, and the overall area is reasonably well-balanced, which is convenient for the overall effect after construction.

Place the product on a flat object, face down, and put a layer of soaked white cement on the back with a trowel. About 5-8mm, then lift it up and look at the opposite direction and stick it to the wall along the side line of the wall. Use a rubber hammer to gently tap the surface to shake out the cement slurry. Grab the white cement dry powder and sprinkle it on the slurry.

Surface treatment, after pasting, use a brush to gently brush off the extruded cement on the surface, and the edges are neatly finished.

The whole is finished with cement solidification, the surface is cleaned, and it is enough to brush twice with stone protective agent. It is recommended to use oil-based protective agent for smooth surface and water-based protective agent for matte surface.

We have 21 years of mosaic production experience, and we can accept customization. At the same time, we also have a large amount of inventory